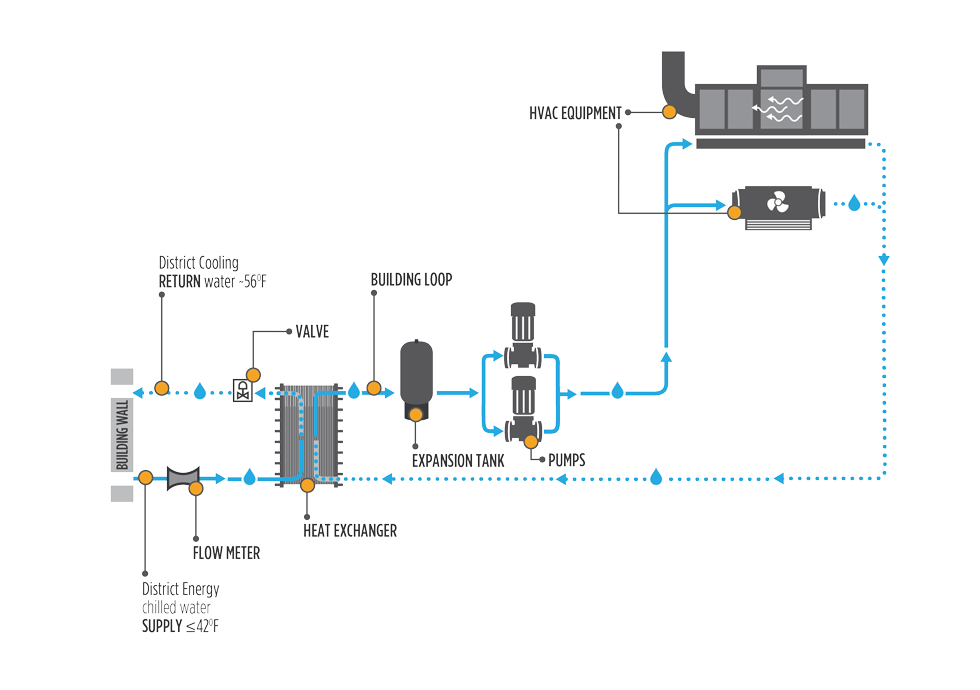

District Energy St. Paul provides year-round chilled water services. Chilled water is generated at the central plant as well as satellite facilities, then circulated through an underground network of pipes to buildings connected to the chilled water system. Customers use chilled water to cool interior spaces, restaurant refrigeration, industrial processing, as well as providing primary data center cooling (when paired with proper backup). The system’s chillers use a mechanical compression cycle to reduce the temperature (or extract heat) from the water loop network. Once the temperature of the water is reduced, it is circulated to the buildings where it removes heat and humidity from the internal spaces, which cools the air. The heat removed from the building is captured in the return water and returned to the plant to start the chilling process again. In addition to air conditioning, customers use chilled water for refrigeration and process.

The system circulates its volume of over 1.5 million gallons of water per hour, with a supply temperature of chilled water between 38°F and 42°F (on average). Cooling service has proven to be just as reliable heating service, exceeding 99.99% since service began.

District Energy utilizes electric centrifugal chillers and the system is connected to chilled water thermal storage. This allows one off-site chiller or production asset to replace multiple chillers in multiple buildings, allowing higher efficiency for production and for customers. These cooling systems are flexible when managing load and during extreme weather events. District cooling significantly reduces the use of ozone-depleting refrigerants, lowers potable water usage at the building, and uses energy more efficiently.