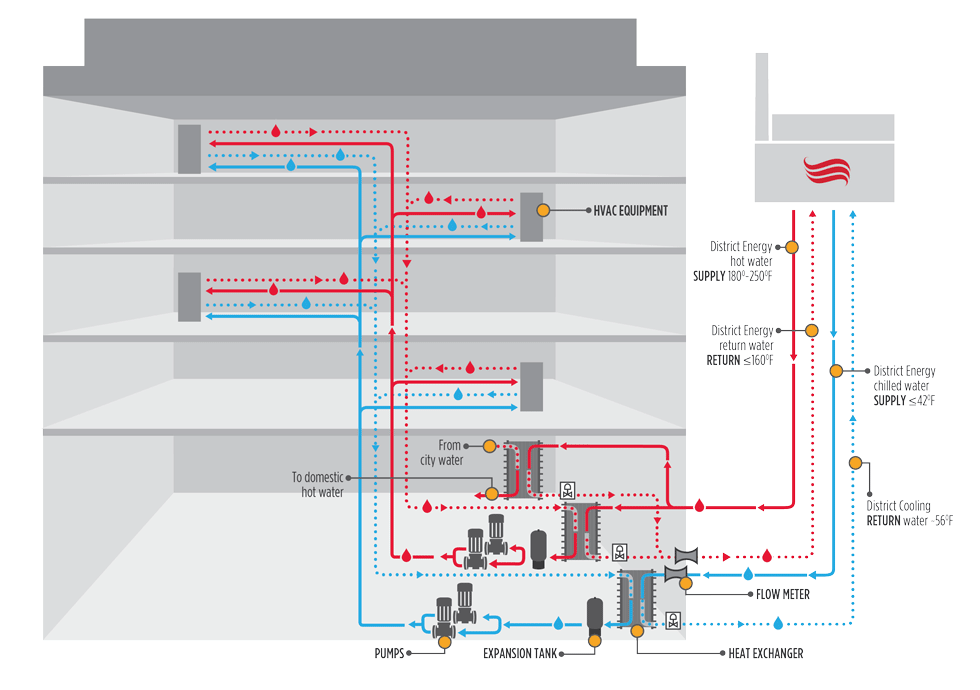

Customer mechanical systems are designed so that the District Energy hot water and chilled water can meet all of the heating and cooling needs throughout the building. Hot and chilled water are produced by District Energy at the plant and then circulated through a network of underground pipes to customer buildings. The District Energy network is referred to as the “primary” water loop. At the customer building, the District Energy supply water is piped through a building wall into the mechanical room. In the mechanical room, the primary supply water travels through a heat exchanger and transfers energy to the water in the building’s “secondary” water loop. The customer’s hot or chilled water is then pumped through the building to provide thermal energy to systems and equipment like HVAC, domestic hot water, and snow melt. Once the secondary water has provided heating energy to the building’s systems it returns to the heat exchanger to be reheated from the District Energy primary water supply. The cooling process removes heat from the customer building and transfers the heat to the District Energy primary return water through a heat exchanger. Once a customer building draws the energy it needs, the water is returned to the central plant for reheating or rechilling then recirculated through the closed-loop piping system.

Each customer’s mechanical interface is customized and may vary in design and function.