A few key activities can help you optimize your cooling system and manage monthly cooling demand. These efforts include starting equipment at minimum speed and ramping up to operating conditions, staging individual equipment start up schedules, and tuning flow control.

There are several measures that can be taken to stage equipment start up, including staggering when units are scheduled to start and limiting their output with a ramp function. Ideally, your peak cooling demand should occur during peak cooling conditions, following the weather patterns and occurring in late afternoon when the outside air and building are at their warmest. When controls are not programmed to stage equipment start-up, a false demand peak can be set first thing in the morning when equipment comes online. There are a couple of ways to stagger equipment. First, if air handlers and pumps are powered by a VFD, change the programming so that this equipment starts at minimum speed. This will allow the air and water systems to move less fluid around the system limiting the output of each device when temperatures are the farthest away from the normal operating condition. Once a control valve for a loop has been able to control the leaving fluid temperature to its respective set point, then the pump or fan can ramp up its speed slowly over 30 to 60 minutes depending on the size of the system, slowly bringing the building temperature down without setting a morning peak. If you have only a few large air handling systems, staggering the start by 15 to 30 minutes will further reduce the chances of setting a peak at startup.

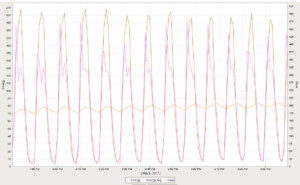

Another method for managing monthly cooling demand is to tune flow control. A hunting control valve will generate times of peak load followed by almost no load. By improving the flow control on the valve, a more steady demand can be achieve avoiding high peaks, and it is easier on equipment keeping the pumps, valves, and motors at constant operation. The graph to the left shows a building that only needs to average 70 tons an hour but peaks at 180 tons for 5 minutes and then drops off to 5 tons for 5 minutes. This variation between too much cooling and then too little cooling impacts building occupants. For optimal thermal comfort slow transitions should be made to eliminate these variations.

Another method for managing monthly cooling demand is to tune flow control. A hunting control valve will generate times of peak load followed by almost no load. By improving the flow control on the valve, a more steady demand can be achieve avoiding high peaks, and it is easier on equipment keeping the pumps, valves, and motors at constant operation. The graph to the left shows a building that only needs to average 70 tons an hour but peaks at 180 tons for 5 minutes and then drops off to 5 tons for 5 minutes. This variation between too much cooling and then too little cooling impacts building occupants. For optimal thermal comfort slow transitions should be made to eliminate these variations.

If you have questions about implementing these measures in your building, or if you would like additional assistance to get the most from your District Energy cooling connection, please contact our team at 651.297.8955, email info@districtenergy.com, or support request form.