This is the one of two articles that will focus on getting the most out of your building automation system. In this article, we will share some suggestions on using totalizers to verify equipment run time and using pressure independent valves to monitor energy. Building automation can help building engineers monitor, integrate, and control building systems from air handling units to lighting. By taking some time to set up some operational parameters, you can gain insight beyond past trends and failure alarms to identify problems in system function. Many control points or objects have built in features that take a few steps to enable.

The cheapest and easiest way to save energy is to simply turn off equipment when it does not need to run. A basic step in setting up a building’s automation system is to establish a schedule. Scheduling generally reflects building occupancy and tells equipment when to turn on and off to accommodate the needs of the people in the building. With a schedule in place, you can set up a simple cross-check to make sure that all the equipment is running for the desired amount of time per the schedule by enabling the totalization property on both the schedule object and the equipment status. The totalization property counts all the time that a piece of equipment is running or the hours that the schedule is occupied. By checking the equipment runtime each week against the appropriate schedule it will be apparent if the equipment did not run long enough, ran too long, or may not have shutdown at all. This simple check will help to ensure that you are optimizing the amount of energy your building is saving.

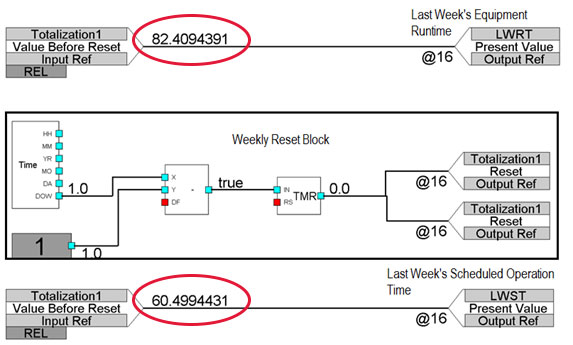

Figure 1 below shows a sample of the programming that includes point totalization, resets, and the value before reset properties of each points. This example shows a fan that ran 22 extra hours above its schedule, which in this case is 35% longer than it was supposed to. Not only does this represent additional fan energy, but it can also represent running cooling or heating pumps longer, conditioning more outside air, and increasing equipment maintenance and repair.

Figure 1: Runtime BMS Calculations

If you have ever wondered if different pieces of equipment run with the same efficiencies or which parts of your building take more energy to provide the same comfort, then installing pressure independent valves and/or energy valves may be a low-cost option to provide some proportional insight into energy saving opportunities. In order to calculate energy usage, you need two things: fluid flow rate and the differential temperature before and after the device. These types of control valves by design allow for precise control for consistent water flow at air handling units, fan coils, and other hydronic devices. Temperature sensors and a well to install them can cost between $50-$100 plus the labor to install them. A good time to install pressure independent valves is when you are replacing existing valves or at the time of new project or major remodel. With these devices, the building automation system can be used to calculate, trend, and totalize the energy being used from each piece of equipment. Weekly or monthly comparisons can be made between different devices as well as the history of the same device to identify when equipment may be using excess energy. This could help to identify issues like plugging or coating coils, failed dampers, and equipment that is taking energy even though its associated fan or pump is supposed to be turned off.

By enabling your totalization settings and adding pressure independent valves, you can enhance your building automation system to gain a better understanding of your building’s actual energy use. In addition to saving money on energy, these tools can help you to identify equipment issues.

If you have questions about energy savings opportunities or your District Energy connection, please contact our team at 651.297.8955, email info@districtenergy.com, or support request form.